Sanitation For Food Flow Chart This white paper summarizes step by step guidelines on how to clean and sanitize food contact surfaces and food processing and handling areas where the possibility of contamination could exist

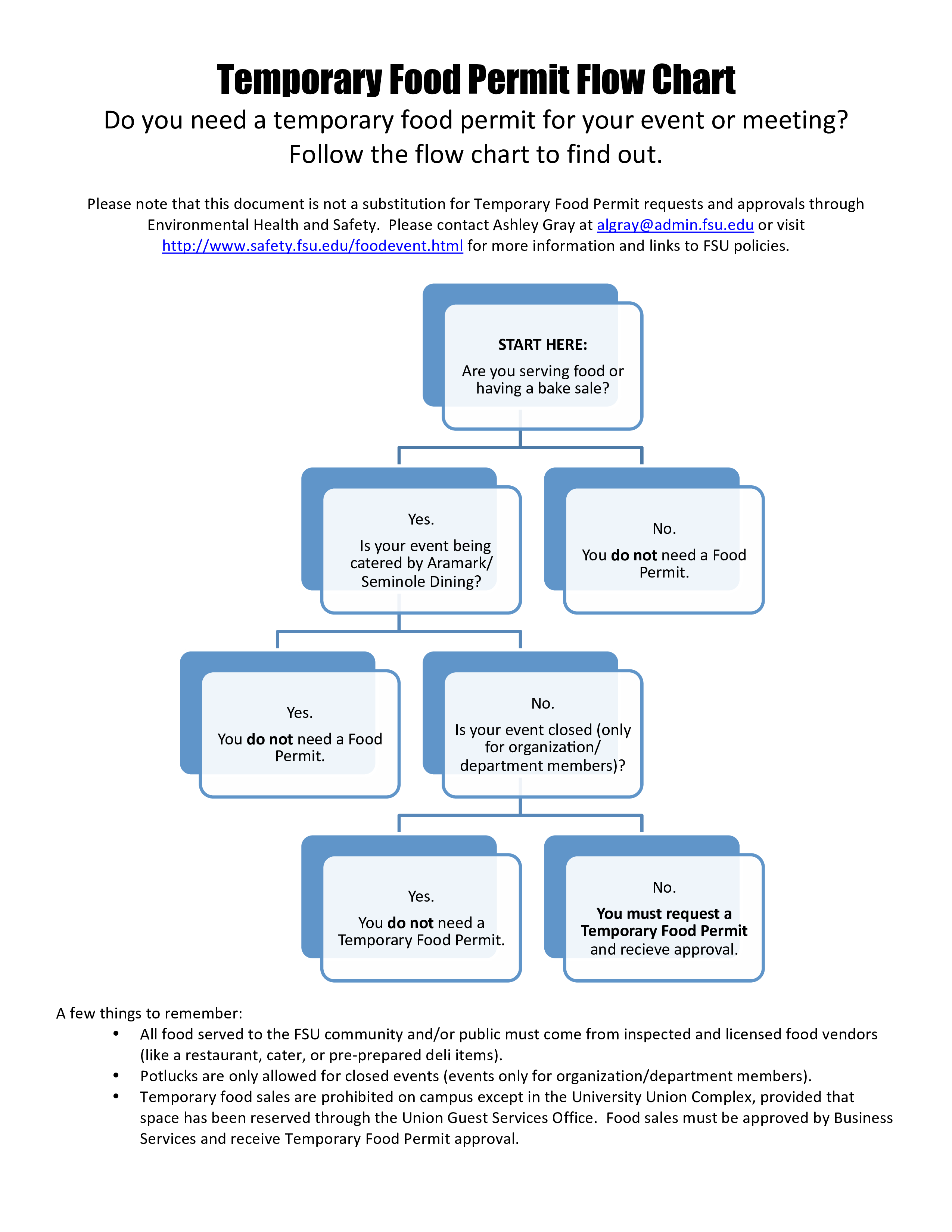

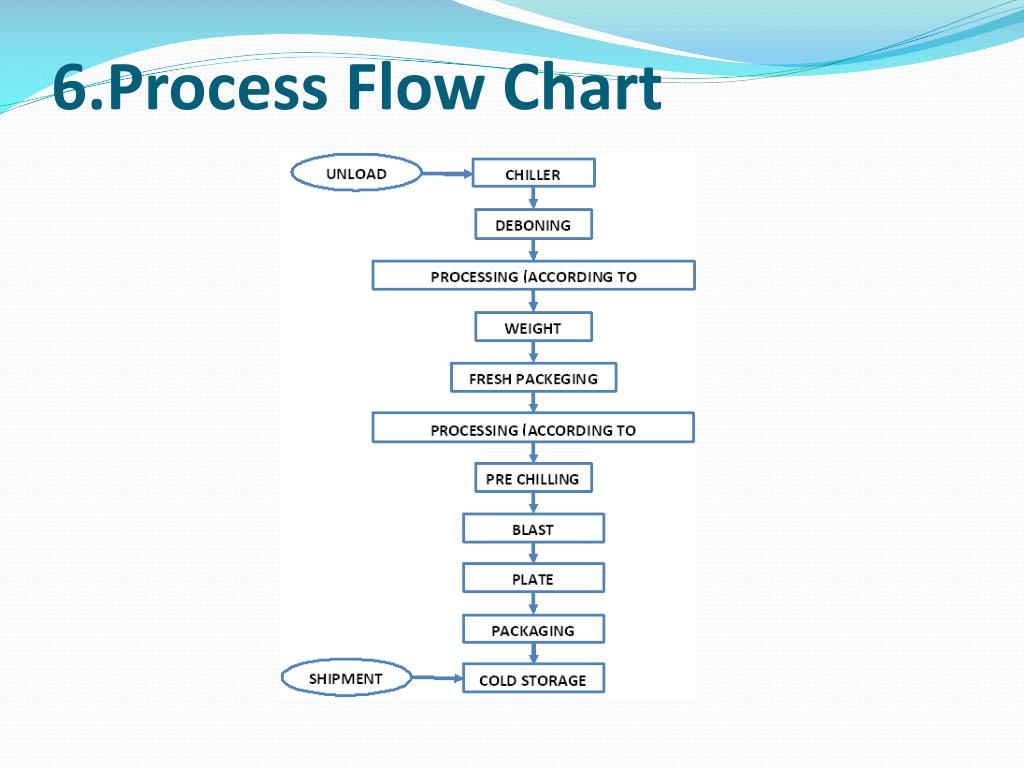

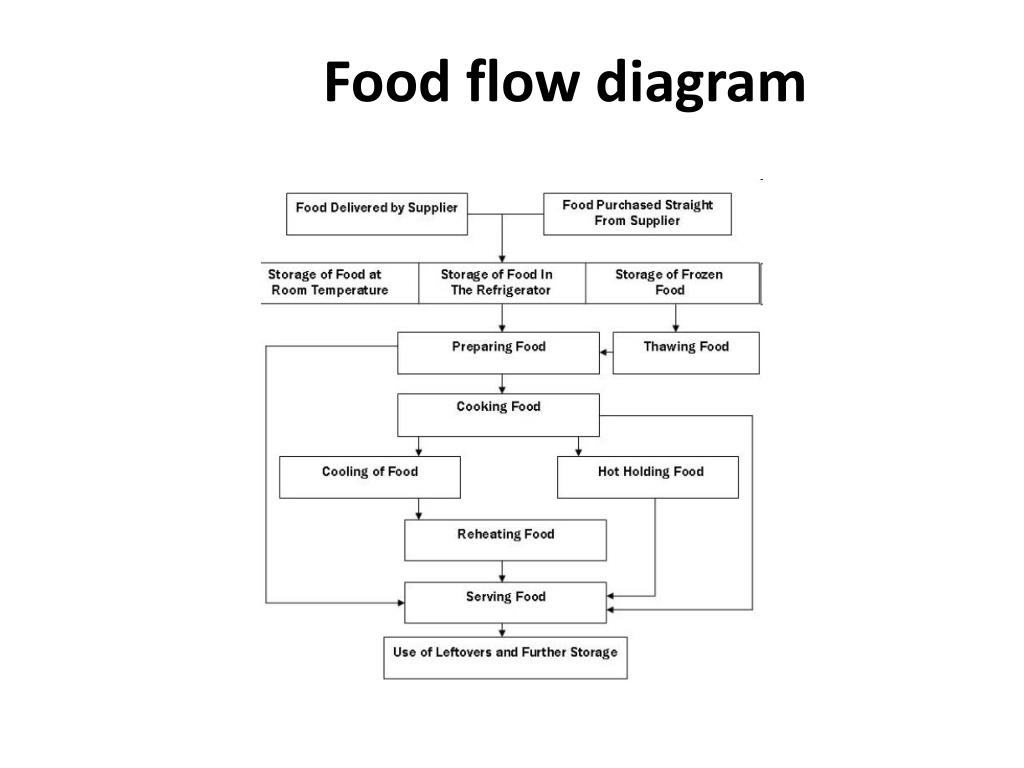

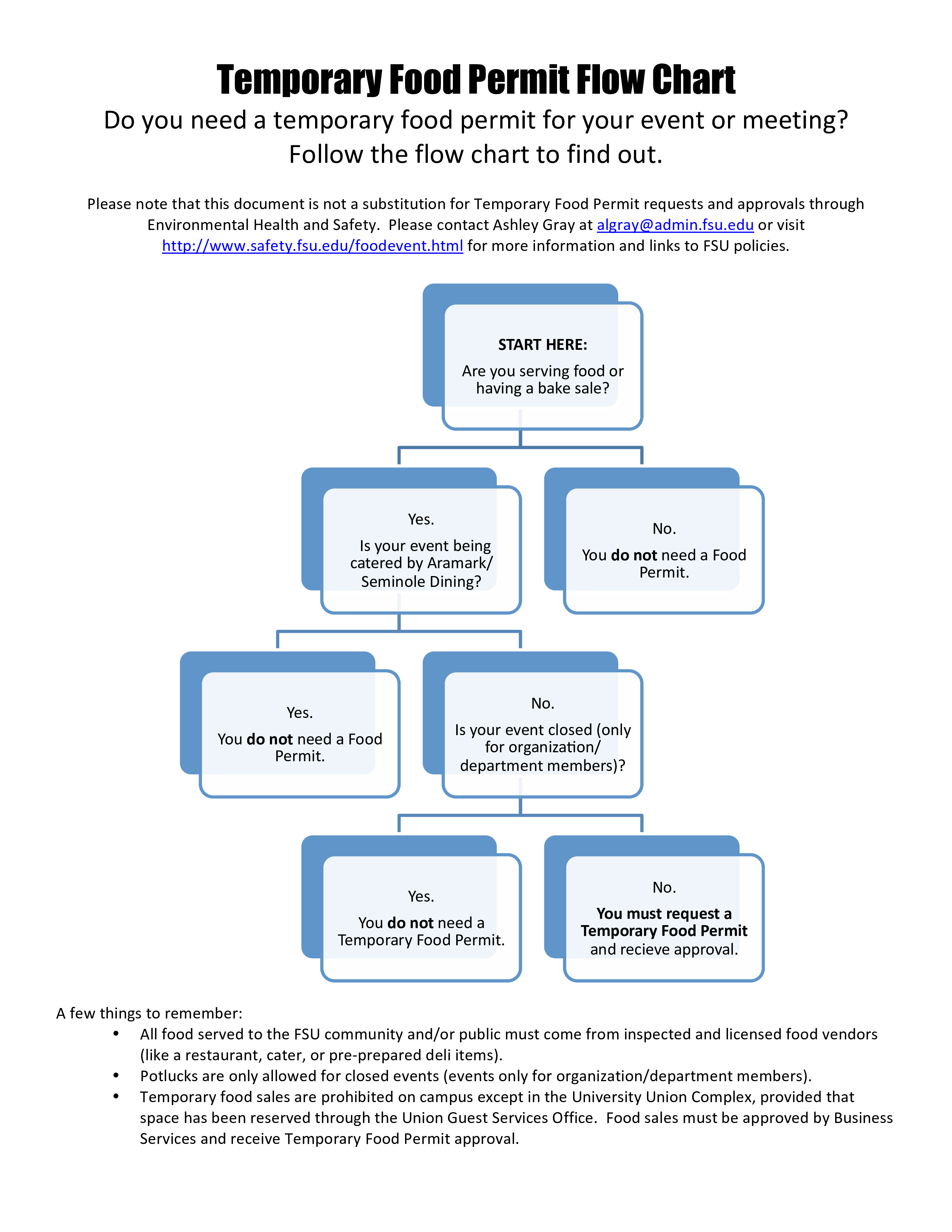

Designing a simple SSOP begins with three basic steps Step One List each product produced by the business and create a flow diagram of the production process Identify all surfaces and equipment used in production Step Two Identify areas and procedures where cross contamination can take place A HACCP flow chart illustrates the journey of food materials in your business from the receipt of raw materials to the delivery of finished products The HACCP food safety system mandates a detailed and thorough food flow chart to accurately identify potential hazards in

Sanitation For Food Flow Chart

Sanitation For Food Flow Chart

https://www.allbusinesstemplates.com/thumbs/142bd5b5-b3e2-4096-b473-7f40c2cafe6f_1.png

Food Safety Flow Chart

https://image.slideserve.com/974011/6-process-flow-chart1-l.jpg

Food Safety Flow Chart

https://image1.slideserve.com/3595544/food-flow-diagram-l.jpg

The simplest form of process flow diagram is linear The key steps in the process are identified laid out step by step and subsequently verified by the HACCP team The diagram shows a Basic flow diagram of your operations Properly identified and analyzed food safety hazards Established critical control points and appropriate monitoring procedures Accurate critical limits Corrective actions for all CCPs Established verification procedure Record keeping procedures for all documents

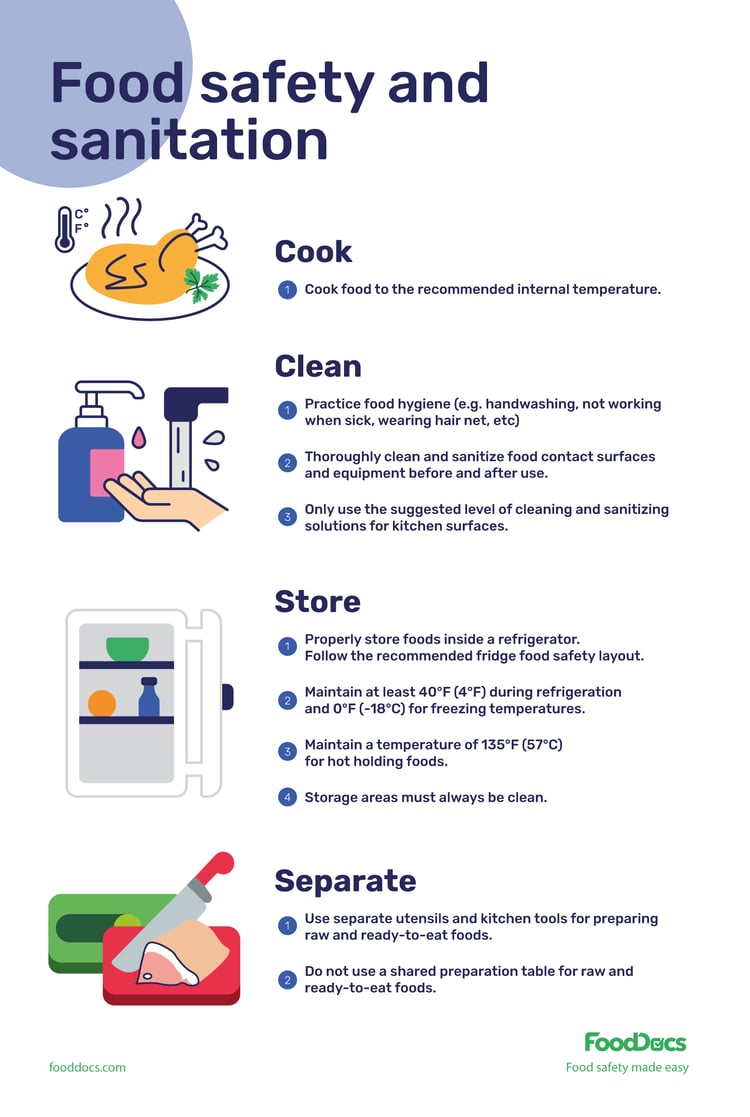

Use our free tool to create HACCP Flow Chart Just replace the words on the form when needed and download Access this editable smart tool We re constantly creating new tools templates posters and checklists to help you manage food safety Please leave your information below to access this smart tool and high quality PDF file Personal hygiene equipment and tool cleanliness pest control and environmental sanitation are all areas to scrutinize when considering an operations ability to control cross contamination Complete a Food safety plan flow chart docx for a recipe or process of your choice

More picture related to Sanitation For Food Flow Chart

Food Security Flow Chart

https://image2.slideserve.com/4474654/flow-of-food-n.jpg

Food Sanitation Spartan Chemical

http://spartanchemical.com/globalassets/sharepoint/media-assets---all-pictures/product-photography/970500_paa_sanitizer_fp_procedures_chart.jpg

Food Manufacturing Sanitation Services Ecowize USA

https://www.ecowizeusa.com/wp-content/uploads/2022/09/food-sani.jpg

Everyone has different styles of teaching and needs within their school district communities When teaching a foods class you may cross over and combine or use frameworks from the five different areas One of the first steps towards a successful sanitation program is to walk through your facility and develop both a flow chart outlining all production or unit operation steps and a checklist to investigate major areas of concern

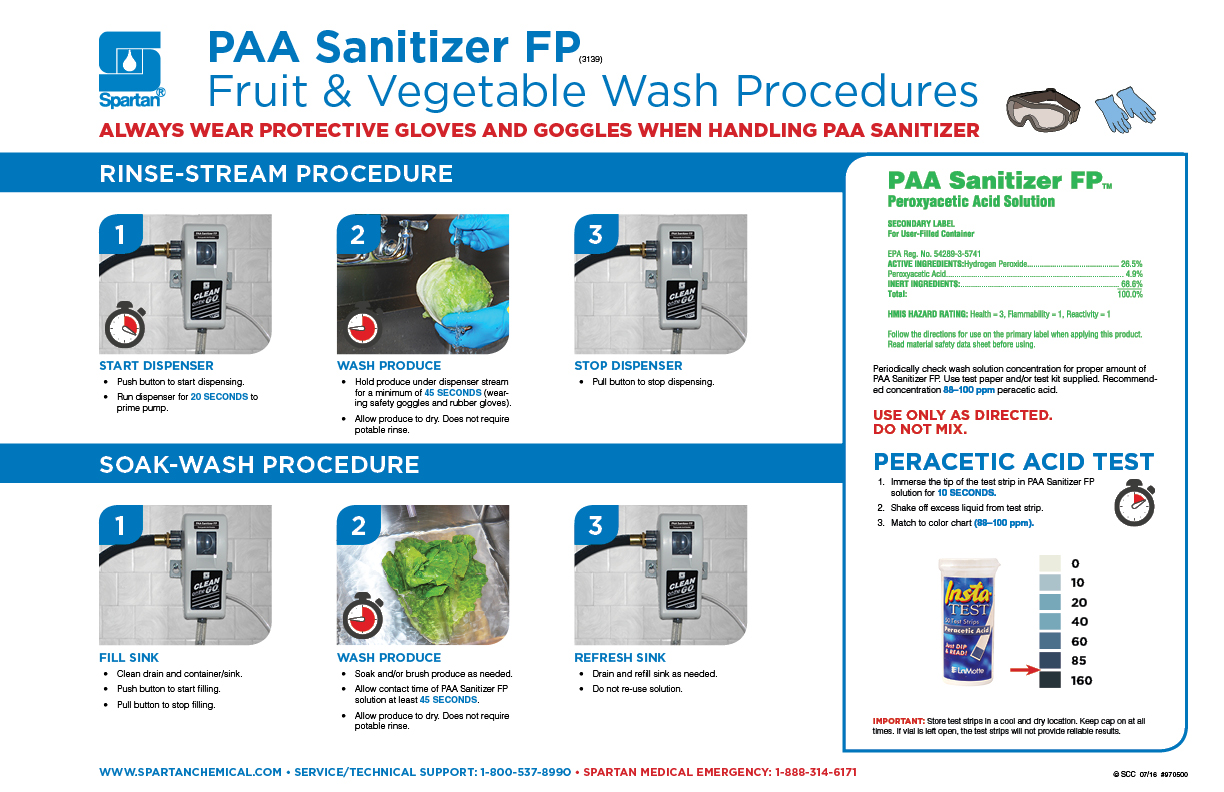

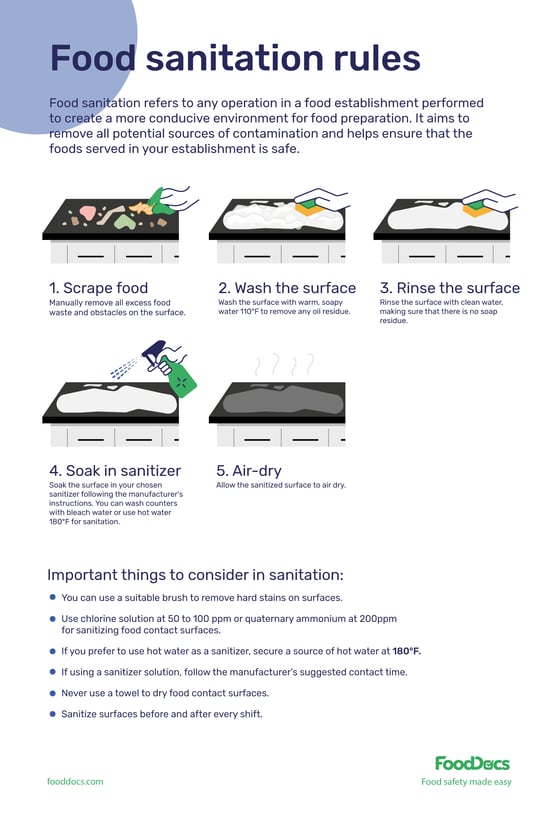

A flow chart demonstrating flow patterns for o Food receiving storage preparation service o Utensils clean soiled cleaning storage and o Refuse service area holding storage and disposal Storage of employee personal items Ventilation including local exhaust ventilation In this step by step guide we ll review each stage of the process and how each step supports the next to ensure a safe clean and sanitary environment 1 Soil Pick up Physically remove soils including dirt mineral salts residues proteins lubricants gross solids and other residues off of contact surfaces Disassemble machinery in

3 Ways To Meet Food Sanitation Requirements

https://blog.slotdrainsystems.com/hubfs/slotdrain-3-1.jpg

Food Safety Sanitation Rules

https://www.fooddocs.com/hs-fs/hubfs/Food_sanitation_F.png?width=550&height=820&name=Food_sanitation_F.png

https://www.nsf.org › knowledge-library › clean-food-processing-facilities

This white paper summarizes step by step guidelines on how to clean and sanitize food contact surfaces and food processing and handling areas where the possibility of contamination could exist

https://farmersmarkettoolkit.org › food-safety › cleaning

Designing a simple SSOP begins with three basic steps Step One List each product produced by the business and create a flow diagram of the production process Identify all surfaces and equipment used in production Step Two Identify areas and procedures where cross contamination can take place

Sanitation Food Quality Safety

3 Ways To Meet Food Sanitation Requirements

Food Safety And Sanitation Download Free Poster

The Food Sanitation Rules Require Someone At Your Restaurant To FOODSWA

Sanitation The Culinary Pro

Why Food Safety And Sanitation Matter For Food Businesses HICAPS Mktg Corp

Why Food Safety And Sanitation Matter For Food Businesses HICAPS Mktg Corp

Top 10 Best Practices Of Sanitation In Food Processing Weever

Top 10 Best Practices Of Sanitation In Food Processing Weever

Food Flow Diagram PDF Foods Foodborne Illness

Sanitation For Food Flow Chart - Basic flow diagram of your operations Properly identified and analyzed food safety hazards Established critical control points and appropriate monitoring procedures Accurate critical limits Corrective actions for all CCPs Established verification procedure Record keeping procedures for all documents